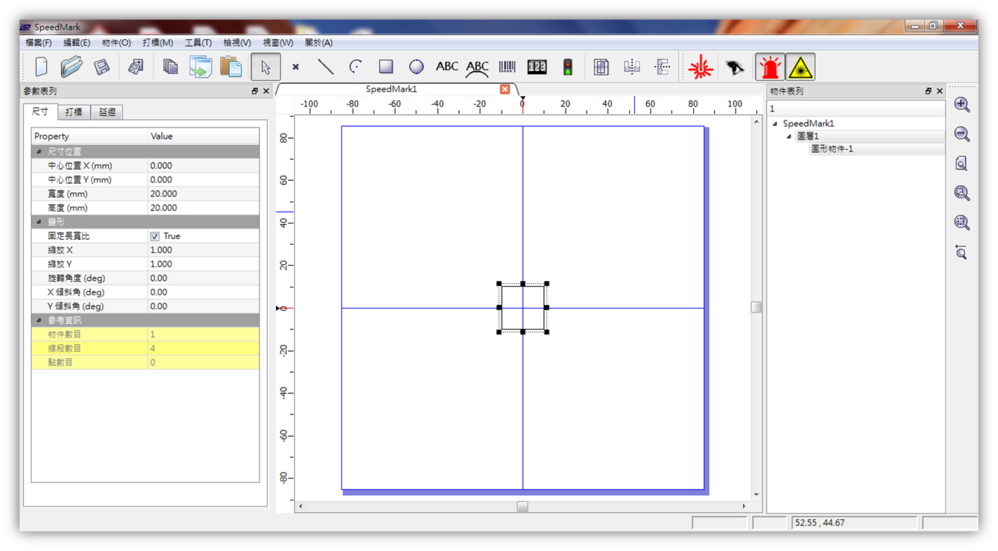

● It has basic drawing functions , Simple graphics can be used without the extra drawing software

SpeedMark marking control software, marking control software, marking software|Taiwan's most professional laser marking leading brand - Laser Solution Technology Co., Ltd

If you have SpeedMark marking control software, marking control software, marking software and other related issues, please refer to the following service content; or directly:+886 2-2677-2894

Particularity:

● It's simple to complete the parameter setting at a few steps

● It has basic drawing functions , Simple graphics can be used without the extra drawing software

● Complete the design of system integration can connect peripheral devices according to user needs

● Unique function of the condition monitoring of laser , users can understand of laser and system status by the instantaneous monitoring

● Optimized set , Just a few steps to complete setting the parameter value for flying marking

● If an exception occurred can automatically stops the laser engraving program , The screen displays causes of exceptions , And outputs a signal for external automation mechanism

● Supports operating systems as Windows 2000/XP/VISTA/7/8

● Supports a variety of driver of laser machine , EX:CO2、SPI、IPG Laser...... .

● Supports image file imported as dxf , plt , dot , jpg , png , bmp

● Supports linking encoders , photoelectric switches, foot switches

● Supports a function to display helical line , serial number

● Supports automation , CCD positioning

● Lens correction can be performed based on the user's demand (Optional)

● Can use flying marking by the conveyor belt with encoders;If without encoder can be used flying marking for the simulation mode of speed

● Extensive functions , Ex:Text , circular text , one-dimensional and two-dimensional bar code , serial number generation , flying marking .... . And to simplify procedures about the related parameter setting , carving work more efficient , easier

DOWNLOAD:Demo Software Download

DOWNLOAD:Demo Software Download